WhichPLM CEO & Founder, Mark Harrop, shares his latest piece with us here. He explores the trend WhichPLM has been seeing in digital partnerships within RFA, and what he refers to as the ‘disruption race’.

Recently, I’ve noted mergers and acquisitions becoming more common in the RFA (Retail, Footwear & Apparel) technology sector, including companies from both the PLM and ERP landscapes. Added to this, I’ve also seen a surge in partnership agreements, where noncompeting companies are increasingly joining forces to share their unique digital assets – assets that, when shared and used together within PLM or a ERP platform, will help to generate significant value for end users. Of course, this has the added effect that each of the technology suppliers working together will have help in gaining ground on their rivals.

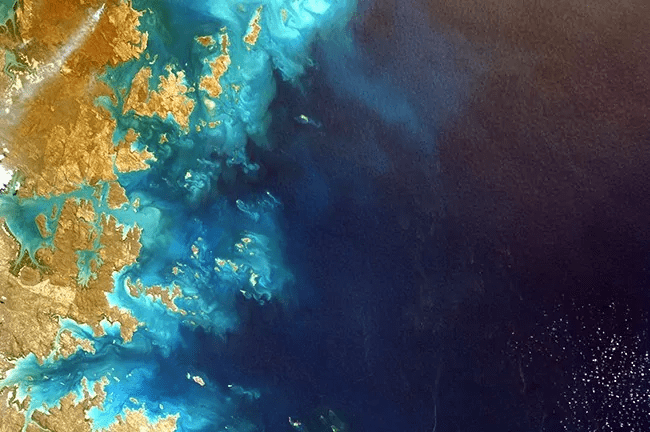

In the PLM sector, several of the market’s leading vendors have now started the ball rolling and begun courting potential partners, as well as building out their developer ecosystems to generate API-driven (Application Protocol Interface) integrations to a wealth of new E-PLM (Extended PLM) solutions that will help to light up the ‘black hole’ of the supply-chain.

These partnerships and ecosystems are already beginning to disrupt the status quo of our industry, and I believe fashion will follow other industries down a road where the disruptors will thrive, and those they disrupted will have to scrabble to reclaim lost ground.

The power of many

I’m sure, like me, you’ve all heard the term “the power of many”. Like Henry Ford said, “If everyone is moving forward together, then success will take care of itself”. With the IoT tsunami heading toward various industries, including our own, we can expect to hear of many more technology businesses harnessing that power by joining forces with partners who can help them – and their customers – flourish in a changing world.

First, these vendors will integrate their joint-venture added value data (I like to call this type of data the “fuel” for PLM), be it trend data, customer analytics, planning data, vector sketches, colour libraries, 2D patterns & 3D CAD files, textile & print libraries, BOM (Bill of Materials), components, packaging, labels, BOL (Bill of Labour) or standards to support costing and sustainability. The list of potential data integrations (and the range of E-PLM solutions that will generate and use it) goes on, and over the next couple of years I would expect the number of these solutions to run into the hundreds (tied to the complexity of a company’s product types), all collaborating and sharing data together, and creating in a new “value-chain” based upon the power of many.

It’s no surprise, then, to see RFA technology vendors following in the footsteps of other industries that are already benefiting from smart, connected networks of computers, systems, hardware and software throughout their supply-chains – industries that have already built on their own disruption and seized the opportunity to work with partners who can add value to as many stages of their products’ lifecycles as possible.

As I mentioned, RFA industry is ripe for disruption – especially when we consider the way that we design and place orders; even in 2016, we’re still operating in the dark ages when compared to other industries. In the last couple of weeks I watched a TV programme on how Walkers crisps (the British equivalent of Lay’s potato chips) are made, starting from potatoes being harvested on the farm, and tracking the process all the way through to a single bag of crisps placed on the shelf at a leading supermarket. At 16 hectares, the Walkers site in Leicester is the biggest crisp factory in the world, producing eleven million bags each day – all of which are monitored at every stage of the process, with intelligence available down to the single bag level.

We, by contrast, are an industry that is still sending technical specifications via email in the vast majority of cases, or via a supplier PLM portal for those that have invested in a modern PLM solution but are still treating it as a PDM system (with all the usual excuses that go with poor implementations). Even in the very best-practice cases, where data is shared bi-directionally in real-time using an advanced PLM solution platform, essential elements are still all but invisible from an intelligence point of view. Product pricing is often still managed and negotiated outside of the primary enterprise solutions (PLM & ERP), shared via email or via the RFQ (Refer for Quotation) process supplier quotation portal.

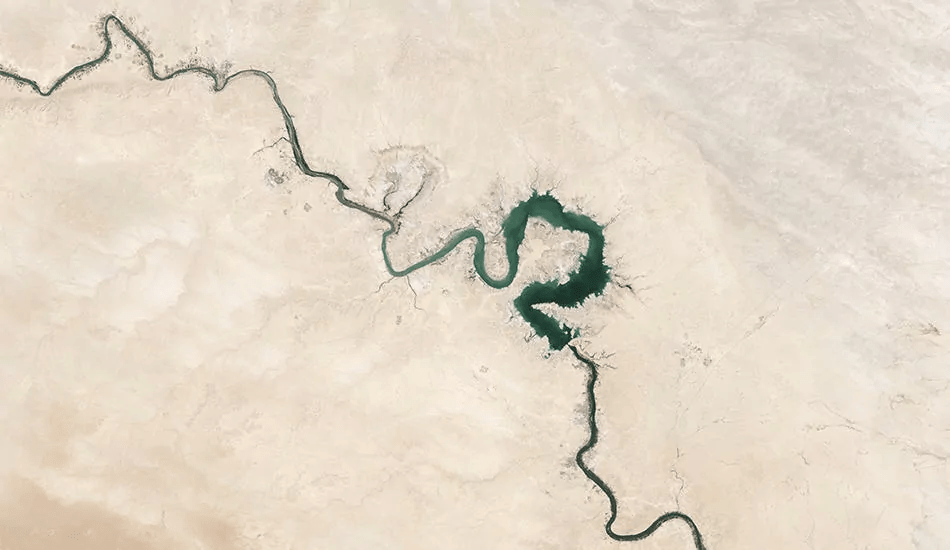

Once orders are officially placed, be it for samples (and there is no real system support here, at least in the main) or bulk production, they then fall into the aforementioned “black hole”. From this point onward the vast majority of communication is still handled via email, and when things start to go wrong then people revert to urgent telephone calls. They then spend the next several weeks or even months constantly chasing the goods with little to no real visibility of where the products are in their lifecycle or what’s really happening.

We’ve been writing for decades now about the need for PLM vendors to develop open APIs, “join the dots”, embrace Digital Transformation, and many other terms for essentially the same thing. These all describe the requirement for solution integration, transparency and collaboration – the increasingly pressing need for people, processes, software and hardware to work together. Sadly, I have to say that, having been around since the first PDM systems came into the RFA sector, we’ve made very little progress when compared to other industries.

This slow approach to a long-existing problem will leave many of the traditionally slow moving RFA-technology vendors wide open to be pushed aside in the coming years. For every large, multi-million dollar vendors there are three or four new, nimble developers who recognise the opportunity to look at the RFA supply-chain with a new set of eyes. And if this means being disruptive, then I say please, bring it on!

When you stand back and look at the sheer volume of inefficiencies you can easily see that there are indeed massive opportunities to be gained by those “disrupters” (the first movers) and their partners, who are clearly already gearing up to reinvent the RFA supply-chain. So, the race is clearly on to transform the way things are done, but what might a new generation supply chain look like? Well, here are a few suggestions for how a brand or retailer looking to make the change might approach things:

- Identify and map the leading supply-chain technologies and partner solutions, along with each of their data inputs and outputs.

- Forge value-added partnerships and contractual agreements that will help to deliver mutual benefits for vendors, partners and users of PLM platforms.

- In my recent post on the subject of the IoT RoI (return on investment), I point to the supply-chain as delivering significant value – perhaps worth reading in conjunction with this post ‘The IoT Transforming the Fashion Supply Chain.’

- Use of common digital (materials & component marketplace) libraries with bi-directional dynamic feeds, allowing user requests for material newness; tag each data element with supporting meta data and store the current available data on a single shared PLM platform.

- Allow PLM users to browse and download partner library data, using open standard APIs, specifying how software components should interact with each solution.

- The industry will also need to re-examine and develop new costing models and incentives for platform sharing.

- The growth of digital data will necessitate a cross platform analytics engine to make sense of the huge amounts of data, insights and predict trends.

- DAM (Digital Asset Management) is an important requirement in any modern PLM solution; the need will become even greater as more images and data elements are shared across the new digital platform.

- MDM (Master Data Management) is vital. We need to manage our master data because, in the newly-integrated world, it will be used by multiple solutions, and an error in master data can cause errors in all the connected solutions that use it. For example, an incorrect material number in the technical specification might mean the wrong fabric being cut and made or, worse still, despatched to the retailer before it’s noticed. Similarly, an incorrect price on an item master could be a marketing disaster, and an incorrect account number in an ERP Account Master can lead to huge fines for the business and a career-limiting move for the person who made the honest mistake.

- To ensure continuity of the user experience and consistency between solutions, vendors will need to share a common workflow engine, and will need to carefully define a product’s lifecycle status and the “push and pull” triggering that will enhance and reduce unnecessary administration along a given product’s lifecycle.

- Development of apps (smaller-scale but potentially extremely valuable add-ons to the PLM ecosystem) is going to be one of the keys to improving collaboration via the Internet, and thus “Cloud” computing – with its ease of deployment for new functionality – is going to be key to IoT developments. If your solutions are not operating on the cloud then you’re not going to be in the best position to take advantage of new developments.

The companies that win the “disruption” race will be the ones that master all the above and more in the shortest time frame. With the IoT (Internet of Things) already starting to make its mark on the RFA sector, it’s only a matter of time before we start to see its tentacles reaching out into the supply-chain, enabling a broad range of computer systems, hardware, and even individual products to talk together seamlessly. These disruptive vendors and their partners have never been better placed to answer the question of integration, so, as I said, “disrupt or be disrupted.”

The world can change quickly

Vendors be warned: you can’t afford to stand-by and wait to see what’s going to happen with regards to the IoT. You need to move fast to maintain market share and to hold onto your current market. Another important reason why the traditional RFA PLM & E-PLM vendors should not wait around too long, is that we are starting to see new PLM entrants that have little or no visibility of the past and who don’t see problems, all they see are opportunities to do things simpler, better, and smarter.

And these disruptive, transformative forces coming into the RFA market. And just like Uber, AirBnB and the other similar disruptive platforms that have changed the way entire industries operate, their impact is going to be fast and irreversible.